Our Services

VISCA International has a long track record of successful project delivery. We have consistently won commissions from the world’s major energy companies, and the knowledge that we have acquired from this experience provides the bedrock of the benefits that we can offer you. The core skills offered by Visca are as follows:

Quality Control and Inspection

Quality Inspection

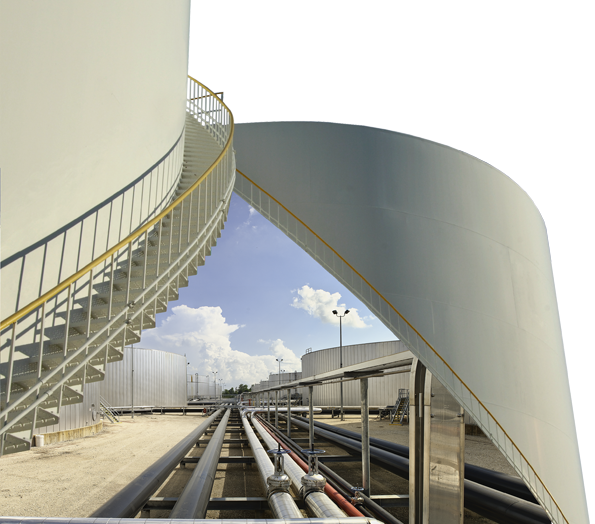

- API 653 Standard Storage Tank Inspection

- API 570 Piping Inspection

- API 510 Pressure Vessel Inspection

Quality Control

- QA/QC compliance/witness/audit etc

- Data collection, report and monitoring

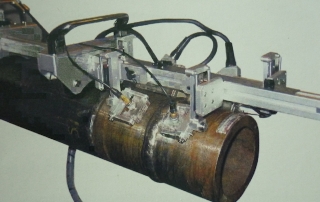

Non-Destructive Testing (NDT)

- Dye Penetration Test (DPI), Magnetic Particle Indication (MPI)

- UTTG, UT Flaw

- Hardness Testing

- Phased Array Ultrasonic Test (UTTG/UT Flaw, C-Scan, B-Scan)

Registration of Certification Machinery

- PMT, PMA and PMD

Calibration Verification and Validation

Calibration check and table, verification and validation

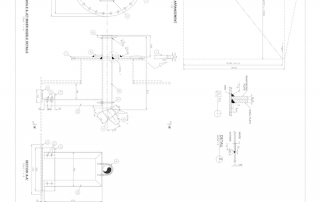

- Storage Compartment (Vertical/Horizontal Tank, Silo, Product Storage)

- Pressure Vessels (Spherical, Horizontal, Vertical)

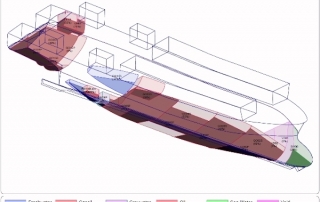

- Ship Tank (Ballast, Cargo Compartment)

- Pipe/Piping

Survey and Measurement

Technical Survey and Measurement

- Tank Settlement, Roundness and Verticality survey

- Structures and tanks settlement, movement, deflection, failure data survey and monitoring.

- Stockpile survey of dry bulk commodities

- Dimensional Control Survey

- Detailing Survey

- Underground Mapping Survey

- Geotechnical survey and analysis (New or existing structures)

Product Survey and Measurement

- Trade Quality and Quantity Survey (TQQS)

- Bunker Quality and Quantity Survey (BQQS)

Marine, Cargo Survey and Measurement

- Draft Survey

- Damage Survey

Asset Integrity Assessment

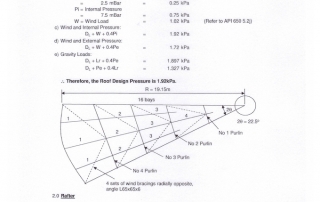

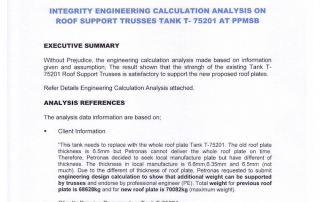

- Tank Structure Engineering and Calculation Integrity analysis

- Tank Design Review and Verification

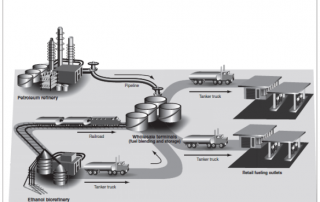

Terminal Specialities

- Terminal Operation Services & Consultancy, Efficiency Improvement Consultancy, Operating Procedure Review

- Facilities Performance Analysis and Assessment, Readiness Audit, Pollution and Contamination Prevention

- Product Lost Prevention, Control and Investigation

- Blending Training Program